Moving Forward: Next generation battery module tester shipped. Potentially unlocking the circular battery economy!

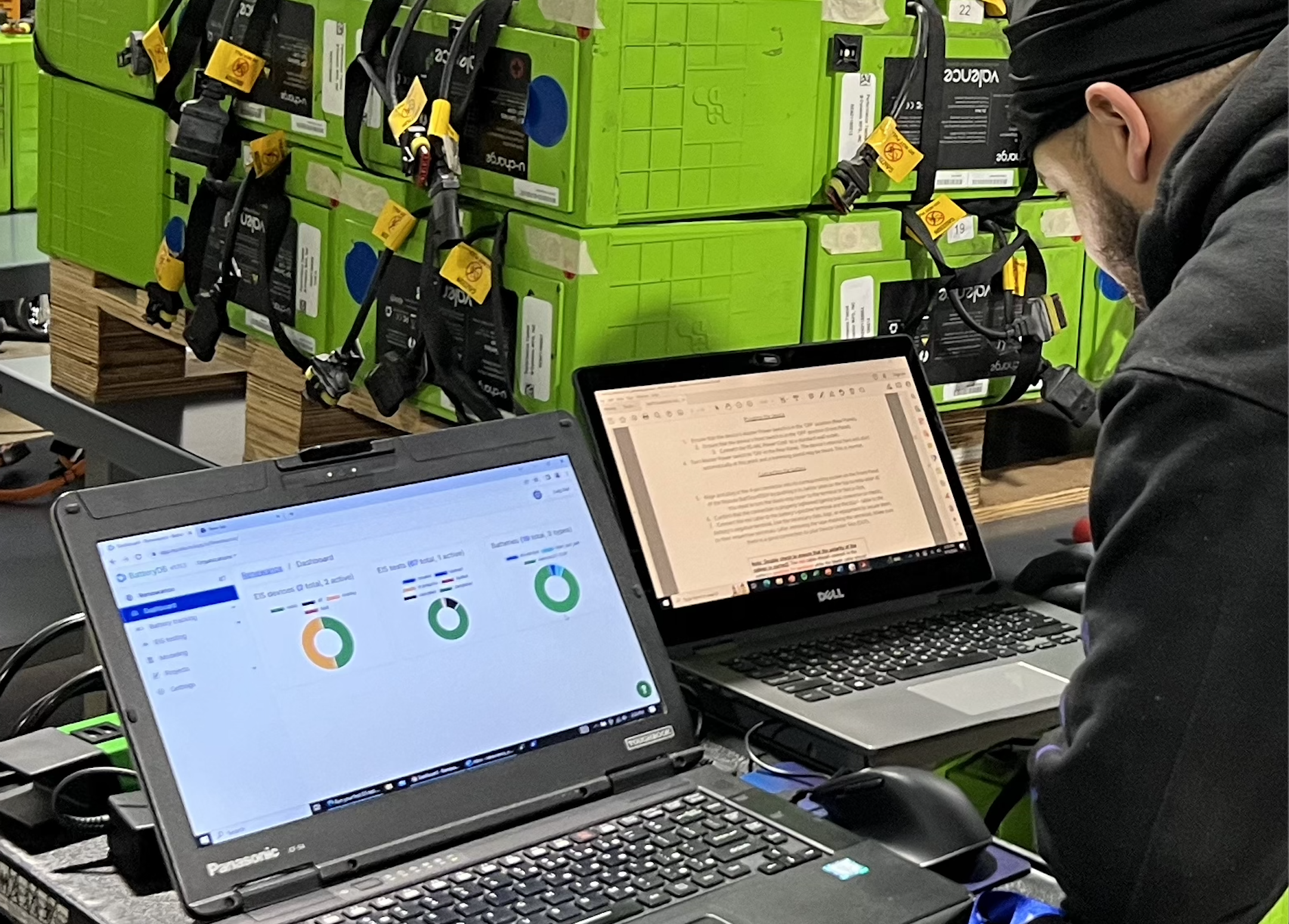

We are excited to announce that ReJoule just shipped prototypes of our next generation battery module tester.

Currently, testing a used battery requires charge-discharge testing, which can take more than ten hours using expensive equipment. Practically speaking, you can only test one battery per piece of equipment every day. So, how can this industry possibly scale if it takes ten hours to test a single battery, when millions of batteries will require testing?

Without rapid, accurate battery diagnostics, it will be impossible to test and reliably repurpose all of these aged batteries. Our cutting-edge battery diagnostic product can test batteries 36x faster, cutting the time required from 10 hours to 10 minutes, while reducing testing operations CapEx and Opex by over 50%. The device, coupled with our BatteryDB cloud-based battery data platform can unlock the potential of the battery repurposing industry, which is expected to reach a value of $30 billion by the end of this decade.

Sponsored by the REMADE Institute and the Department of Energy (DOE), ReJoule’s technology also promises to be transformative for the used EV market. “Imagine buying a used electric vehicle and having no idea whether the battery is likely to last years or is on the brink of failure? That is the reality today,“ notes Steven Chung, ReJoule’s Co-founder CEO . “Our technology makes it possible for consumers to be confident in what they’re getting and for dealerships to actually know what they’re selling. Replacing a battery can cost $20,000. Today, no one can tell you if the most expensive component in an electric vehicle is any good.”

ReJoule’s device will be used by Renewance, a leading battery supply management company, to rapidly test and assess used batteries from more than 50 electric delivery trucks. Renewance will be able to test more than 1500 battery modules in the upcoming months with this first device. The results will be benchmarked against the prevailing method of charge-discharge testing batteries. This is only the beginning. Before the end of the year, ReJoule will deliver a device capable of accurately testing battery packs of 200V to 500V in less than 10 minutes.

“This is a giant leap in battery diagnostics,” said Zora Chung, ReJoule’s Co-Founder and CFO. “One 3% of auto technicians are trained to work on high voltage batteries. Our product is meant for the other 97% - Our technology makes the process a lot simpler.”

We are moving forward. By the end of 2023, we will be able to test electric vehicle batteries without removing them from the vehicle, by simply plugging them into the charging port. If you need to test your batteries, we have your fastest, and easiest solution that maintains a high level of accuracy and safety.

Contact us at info@rejouleenergy.com if you want to leverage our technology to test your batteries. What are your thoughts? Did we leave anything out? Please comment and share so we can all engage in conversation and learn from each other.

Cheers,

The ReJouligans